Brussels start-ups are reinventing construction materials

The Brussels-Capital Region is full of SMEs that produce biosourced materials. We met with Camille Mommer (Natura Mater), Nicolas Coeckelberghs (BC Materials) and Stephan Kampelmann (Sonian Wood Coop) who spoke to us about the dynamic and future of this promising sector.

Why did you start your company?

Nicolas Coeckelberghs: thousands of tonnes of earth are excavated in Brussels every year. Most of the earth is dumped or buried as waste, even though the material is perfectly reusable and 75% non-contaminated. This was the starting point for BC architects & studies’ launch of BC Materials in October 2018. Since then, we’ve been using the excavated earth to make raw earth products – rammed earth and bricks – and coatings at our production site and on job sites.

Stephan Kampelmann: In 2019, we realised that significant amounts of lumber were being produced in the Sonian Forest, and that virtually all of it was being exported to China. And that, in the meantime, Brussels was importing wood from Asia, Russia and Canada! We created our cooperative to promote the local use of wood from our ecosystem. A network of self-employed lumberjacks, sawyers and carpenters work with us on a regular basis on construction projects. The beech from the Sonian Forest, planted 200 years ago, is well-suited to many applications including stairs, floors, cladding, tables and work surfaces.

Camille Mommer: The Natura Mater project was started in 2019. Jérémy Boomer, an architect and general contractor, wanted to renovate his house as sustainably as possible. He realised that, even with his experience and extensive network, he was having trouble selecting the right materials to use. This meant that the task would be even more complex for the average person. After receiving coaching from Greenlab for a year, we started our company in May 2020. Our mission is to move sustainable materials from niche to norm by assisting self-employed tradespeople.

Tell us about the projects you started or in which you are involved.

S. K.: Recent projects include the fitting out of the Popotes café in Place Flagey, for which we made benches, work surfaces, shelves, etc. It’s rewarding to have Brussels residents sitting on beech from the Sonian Forest!

N. C.: I would emphasise our research and development missions, notably for public customers like the municipalities and the Régie des Bâtiments. They involve the analysis of (future) earth excavations to find the right formula to use them to make bricks and coatings.

C. M.: Our work consists in keeping up to date with existing materials and materials under development to provide an overview to architects and general contractors about what is available and relevant for their project. We make the connection between them and the manufacturers, test products on partner job sites in order to get real feedback. We also work to counter preconceived ideas about certain sustainable materials. And we identify any gaps in the market place.

In addition to the benefits for the environment, what other benefits of biosourced materials would you highlight?

C. M.: Managing hygrometry is very important for many construction and renovation projects. Materials like clay and lime and insulation made from straw, hemp and grass allow buildings to breathe better than traditional insulation materials. The use of certain materials provides time savings and, therefore, money savings. Materials like raw earth dry much more quickly than traditional materials and don’t necessarily have to be painted or treated.

N. C.: For our part, I would mention the virtually non-existent transport costs and the low use of grey energy. Our products are also entirely reversible and don’t generate any waste. At the end of their life cycle, they can be put back into the ground or sent to us. Of course, there are also the hygrometric properties of the materials, which absorb excess dampness in a room and recover it where there isn’t enough.

How do you see the future of the materials sector and of your company?

N. C.: We’re seeing many positive changes at the government level and that’s excellent. It provides an example and encourages people to build differently and in a healthier way. We’re happy that there is more and more interest from architects who come to see us to understand how to use our materials. Demand is growing and we’re now reaching people who don’t know anything about raw earth and want to know about its performance, understand how to use our products properly and have them co-exist alongside other materials.

C. M.: We’re very positive and enthusiastic because we get the impression that something has changed since June 2021, both in Brussels and in Belgium. Architects and customers are increasingly asking themselves the right questions. I’m sure that we have momentum now, and things are going to shift to a higher level in terms of studying circularity and materials choices, regardless if they’re biosourced, geosourced or from recycling sources. In addition, there’s currently a boom in new product development.

S. K.: We’re in a growth phase, we’re gradually increasing our production capacity, our customer network and our products. Rising market prices are an advantage for us because we’ve become more accessible to new customers.

Let’s keep our fingers crossed that, coupled with political will, the movement under way with producers and architects, customers and general contractors will finally move these materials from niche to norm.

The founders of Sonian Wood Coop, Stephan Kampelmann (left) and Benjamin Moncarey (right) ©The Mirror Films

The beech trees planted in the Sonian Forest 200 years ago are ready for use in a wide range of applications ©The Mirror Films

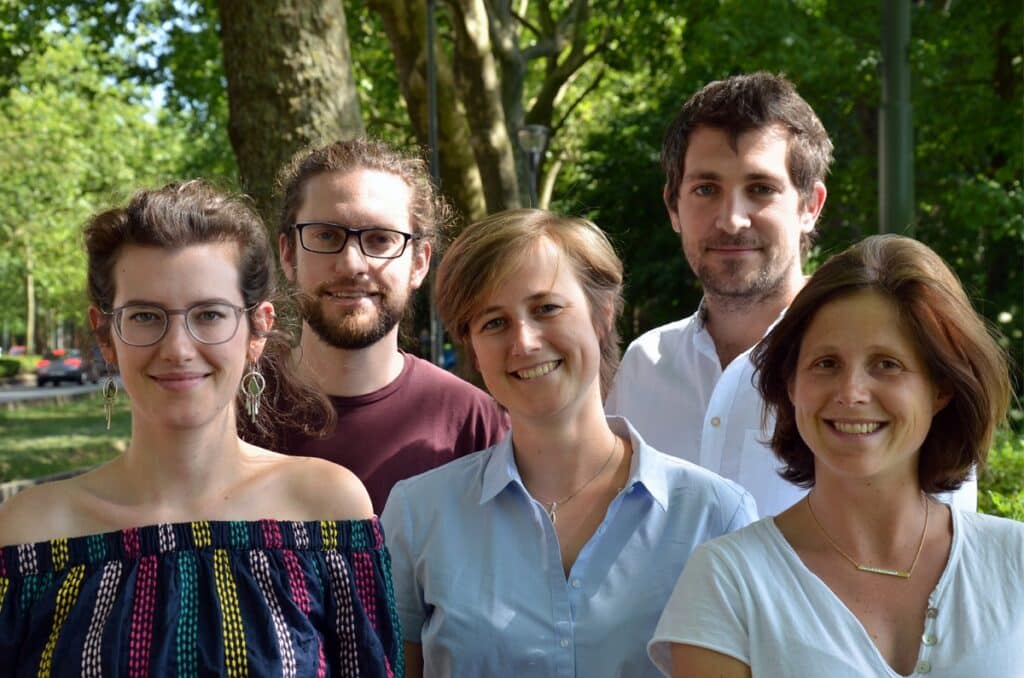

The five founders of Natura Mater – centre: Camille Mommer ©Natura Mater

Natura Mater informs entrepreneurs about sustainable materials and what’s suitable for their projects ©Natura Mater

Nicolas Coeckelberghs ©BC Materials

BC Materials is carrying out more and more consultancy missions. The Usquare project in Brussels ©Sander Lambrix

Thousands of tonnes of earth are excavated each year in Brussels ©DeMeuter

BC Materials uses the excavated earth to make raw earth bricks called “Brickettes” ©Thomas Noceto