Circularity is an aspect that can no longer be neglected in the construction sector, which is still responsible for almost 40% of CO2 emissions worldwide.

In this article, we will discover three innovative circular solutions developed in Brussels that could inspire you for your next construction/renovation projects: the eco-circular green roofs of La Ferme Nos Pilifs, the Safety in Circularity certificate created by SECO Belgium, with the support of BatiTerre and Entreprises Jacques Delens and, lastly, the mycelium-based insulating panels produced by PermaFungi. With the exception of the last example, these companies are members of the ecobuild.brussels cluster, the network of sustainable and circular construction and renovation stakeholders in Brussels, hosted by hub.brussels, the Brussels Agency for Business Support.

La Ferme Nos Pilifs: a social and circular initiative in Brussels

La Ferme Nos Pilifs is a non-profit organisation and adapted work company located in Neder-Over-Heembeek, north of Brussels, which has enabled the professional integration of 145 people with disabilities. La Ferme has several centres, activities and shops, all of which are part of a sustainable and eco-responsible approach.

One of its activities includes the development of green and circular roofs, “A green roof is a flat or slightly sloping roof covered with vegetation. We have added the eco-circularity component by integrating (as much as possible) materials from reuse and recycling and recovered waste into our facilities,” explains Etienne Duquenne, Eco-Gardening Manager at La Ferme Nos Pilifs.

When raw materials are available and the site allows it, the non-profit uses its own circular substrate for its roofs, composed of crushed bricks and pebbles, mixed with compost, which is particularly suited to the vegetation found on the roofs, such as plants of the sedum family. The use of this 100% circular substrate is probably unique in Belgium.

A roof and a world that live better

When covered with a layer of vegetation, the roofing membranes are no longer directly exposed to the sun’s UV rays and are better protected from temperature fluctuations, which considerably increases their lifespan, “An uncovered membrane will suffer much more from the effects of expansion and shrinkage, which facilitates the appearance of micro-cracks and ultimately causes waterproofing problems.” Green roofs also provide natural thermal and acoustic insulation.

In cities, green roofs are particularly relevant to many ecological challenges. In particular, they help to delay water discharge by acting as a sponge, “In the event of heavy rain, green roofs absorb water, which will only be discharged when the substrate is saturated. This unclogs the sewage networks and avoids the dysfunction of the treatment plants.” In addition, rooftop vegetation enhances urban biodiversity by providing shelter for a large number of insect species. Green roofs also provide a cooling effect in the city, as the plants transpire and cool the air.

Let’s not forget the added landscape value and the embellishment of the living environment, when there is a view on the roof because, in the words of Etienne Duquenne, “It is always more pleasant to have a view of a garden than of a black roof”.

A decision not to be taken lightly

Installing a green roof requires a minimum of preliminary obligations and precautions, to avoid problems. The first thing to do is to make sure that the roof’s waterproofing membrane is in good condition because once the green roof is in place, any repairs will involve major work.

Secondly, check the roof’s load-bearing capacity. It would be irresponsible to install a green roof if it is not sufficient, “When installing a green roof, we add a load of at least 100 to 150 kg/m2 onto the structure, which is not insignificant. And, for intensive crops, this can reach 500 kg/m2. It is therefore essential to have an architect or engineer calculate the roof’s bearing capacity,” warns Etienne Duquenne.

A circular programme that makes sense

La Ferme Nos Pilifs recently decided to supplement its circular green roofs offer by launching its own production of plants specifically for these roofs. This is a simple way to further reduce its carbon impact while ensuring organic growing, “It was the next logical step, given our approach. With our own plants, grown in our nursery, we eliminate the problem of transporting them. It also allows us to focus our crops on plants more specifically suited to each type of green roof, further improving the resilience of our roofs.”

The “Safety in Circularity” certificate: support for the professionalisation of reuse

“We need to use more reused materials in construction.” This is a laudable intention, but one that is also crucial in making the construction sector more sustainable. In practice, however, the reuse of materials often comes up against a lack of reliable information about their origin, their condition or the recovery and reconditioning methods used. Understandably, this lack of traceability and information generates distrust on the part of architects and contractors who do not want to take on responsibility by using materials whose reliability is not guaranteed.

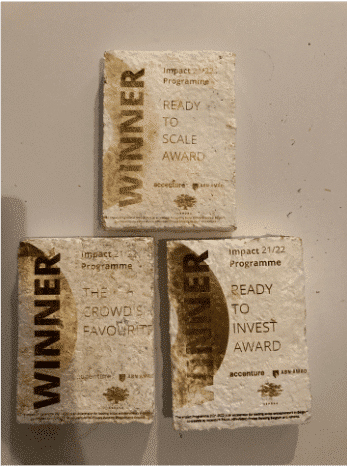

Faced with this problem, since the beginning of January, the independent technical inspection office SECO Belgium has been offering a new certificate, called Safety in Circularity, which recognises the quality of the construction material recovery processes implemented by a company. Selected from among the winners of the Brussels Region’s BeCircular 2020 call for projects, the certificate aims to offer well deserved recognition of the expertise of companies in the field of materials recovery with a view to stimulating reuse.

An initial precise scope

SECO has developed the framework for the certificate based on the field experience of two companies specialised and experienced in reuse in the Brussels Region: BatiTerre and Jacques Delens. Innovation & Development Manager at SECO Belgium, Carine Hiernaux, coordinated the development of this certificate, “We wanted to highlight the professionalism of those involved in reuse to reassure people about the quality of the information on materials made available for a new use. This certificate will allow clients to choose a partner with recognised skills, and conversely, certified companies to highlight their expertise and their involvement in the transition to more sustainable construction.”

A first list of reference materials for the Brussels Region (initial context of the project) has been established thanks to the combined expertise of the three companies. It is now possible to request certification for railings, raised access floors, taps and sanitary facilities. This list is certainly not fixed and the certificate will evolve quickly according to market demands (insulators, bricks, etc.). Three distinct processes have been identified for each material industry: dismantling or deconstruction, treatment and storage. The transparency necessary to create trust in the proposed reuse materials is guaranteed by the provision of the information available for a material, in the form of a product sheet. A technical data sheet template is available, containing the minimum technical characteristics necessary or mandatory to communicate according to the material concerned (lambda value, reaction to fire, etc.).

It is of course possible to be certified for one or more materials, as well as for one or more stages of the reuse process. The certification is flexible and can be adapted to structures of all sizes in all regions of the country.

What is the process?

Any company wanting to acquire this certificate can go to the safetyincircularity.be website and fill in the contact form. This will be followed by an offer which, once validated, will allow evaluation by an independent auditor selected by SECO Belgium. This auditor will visit the company’s head office and then the workshop or construction site to carry out an exhaustive evaluation of the planned reuse stages (deconstruction, treatment, storage) for the type(s) of materials concerned.

If this evaluation is positive, the company is awarded the certificate, which is in the form of a document issued to the company and presents a summary of the types of materials and stages of reuse certified for a given period. This document is accompanied by a certification form that contains the relevant information identified during the evaluation. Once issued, the certificate is valid for three years and is renewable. During this period, the certified company will be evaluated every year to monitor its evolution.

During the first contact, SECO informs the company about the overall process to be followed and the minimum information required to begin the official application for certification. As Carine Hiernaux explains, “This allows us to identify any aspects of the process that need to be improved or changed before the company embarks on its certification process.”

What next?

The certification framework has been designed to be flexible and modular, allowing rapid evolution towards other material types, “If we notice a certification request for a new material type, we will do everything possible to make it available as quickly as possible, because the certification has been designed to stimulate the development of circular construction.” The certificate is already open to any applicant company.

Whatever happens, Safety in Circularity certification represents a crucial first step in the recognition of reuse stakeholders, the development of circular construction and the standardisation of its practices. We can only look forward to future expansions of the initiative.

PermaFungi: mushrooms but not on your plate

Since 2014, PermaFungi has been recovering organic waste, specifically coffee grounds, to produce (oyster) mushrooms in a short circuit in Brussels. The Brussels-based company has gradually increased its activities, making the most of the possibilities offered by mycelium, also commonly known as “mushroom spawn”; it has been making insulating panels for the construction sector for a few months now.

But, before presenting this unique application, here is a short and simple explanation of what mycelium is, by Victor Thomas, Scientific Manager at PermaFungi.

“If we compare the mushroom, as we know it in food, and the apple tree, mycelium would perform the functions of the roots, trunk, and branches of an apple tree but in the guise of a long network of white underground filaments. So the mushroom is just the fruit of the mycelium, a much more complex organism than it appears.”

A twofold approach to waste recovery

The coffee grounds collected by PermaFungi are stored in bags hung in the cellars of the Tour & Taxis buildings. They have small holes pierced in them, through which the oyster mushrooms that grow there will come out. Once the oyster mushrooms are harvested, the remaining soil from the bags is mixed with mycelium before being dried. The result is a rigid substance, somewhat similar to plastic materials in appearance, called myco-material.

Applications under construction

PermaFungi initially experimented with this myco-material in the manufacture of light fixtures and other interior objects, production that is still ongoing today. However, following a call for tenders from the City of Brussels for a carbon-neutral insulating material, PermaFungi produced its first panels using myco-material, as its many properties lend themselves to it. The material stands out for its efficient thermal and acoustic insulation performance, but especially for its flammability.

“It should be remembered that in residential fires, the presence of traditional insulation, such as glass or rock wool, significantly reduces the life expectancy of those trapped by the flames.”

In construction, myco-material also has a great advantage in terms of resource renewal. “If you compare the sources of the materials, it is highly indicative, as mycelium is an organism that grows around 1,000 times faster than a tree,” confirms Victor Thomas.

Although still developing rapidly, PermaFungi has great ambitions and hopes, in the long run, to be able to join a recycling circuit of large companies and industries in Brussels, or within a municipality, by recovering and integrating all its organic waste into its production of myco-materials.

There is still a long way to go to reach the European objectives of a carbon-neutral economy by 2050, but the construction sector is aware of its impact and showing initiative and responsiveness. In this context, development support projects such as the ecobuild.brussels cluster of the hub.brussels Agency are essential resources for increasing the competitiveness of companies with a positive ecological impact and helping to propagate circular practices.

Safety in Circularity

Safety in Circularity

Ferme Nos Pilifs

Safety in Circularity

Safety in Circularity

Ferme Nos Pilifs

Ferme Nos Pilifs

Ferme Nos Pilifs

Permafungi

Permafungi

Permafungi

Permafungi

Permafungi

Permafungi

Permafungi

Permafungi

Permafungi